Adv. Sci.: In-situ nanoprecipitation method for efficient preparation of collagen-polyester amphiphilic composite hydrogel for drug delivery

Collagen is the most abundant protein in the mammalian world. Due to its excellent biocompatibility, biodegradability and ability to promote cell adhesion and proliferation, it is widely used in various forms such as films, hydrogels, sponges, etc. The field of tissue engineering. Among them, hydrogel is the first choice in many clinical applications due to its good moisturizing properties and structural similarity with extracellular matrix. At present, most collagen hydrogels are made of low-concentration collagen solutions (<10 mg/ml), and their poor mechanical properties and rapid degradation greatly hinder their application in the field of tissue repair. In addition, another major drawback of traditional collagen hydrogels is the difficulty of encapsulating drugs. This is because many drugs are hydrophobic and have poor affinity with the collagen network, so they have the disadvantages of low drug loading and obvious burst release.

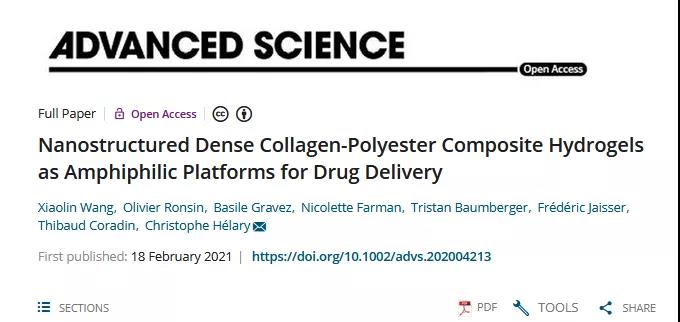

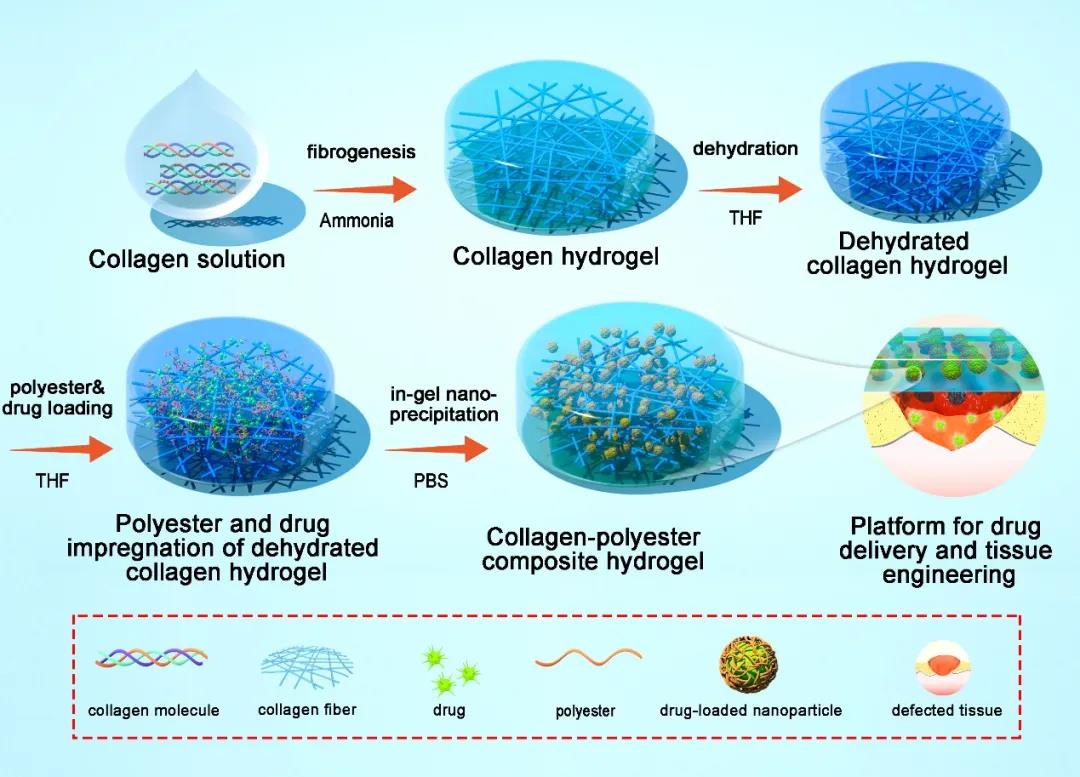

In order to solve the above-mentioned problems of traditional collagen hydrogels, a research paper entitled "Nanostructured Dense Collagen-Polyester Composite Hydrogels as Amphiphilic Platforms for Drug Delivery" was recently published in the top international journal Advanced Science. This paper innovatively applied the Nanoprecipitation method to the three-dimensional hydrogel network system, and quickly and conveniently prepared the collagen-polyester amphiphilic composite system. The nanoprecipitation process is also called solvent replacement and involves two miscible solvents, one is a good solvent for the polymer (here, THF), and the other is a non-solvent (here, water). During this preparation process, when the collagen gel impregnated with polyester tetrahydrofuran solution comes into contact with PBS, water molecules will diffuse into the polymer chains in the hydrogel, thereby forming solid particles in the 3D dense collagen network. .

Through this method, the paper successfully developed an amphiphilic composite platform that combines high-concentration collagen hydrogel (40 mg/ml) and up to 50 wt% of polyesters with different hydrophobicities and chain lengths. Compared with pure collagen hydrogel, composite materials made of polylactic acid-glycolic acid (PLGA) and polylactic acid (PLA) instead of polycaprolactone (PCL) have higher mechanical properties while maintaining high Hydration. The release kinetics of spironolactone (a lipophilic steroid used as a drug model) can be fine-tuned within a month. Unlike the incorporation of pre-formed micro-nano particles, the new process can not only improve the physical properties of collagen hydrogels, but also control the delivery of drugs. More importantly, this process is also applicable to hydrogel systems such as sodium alginate and chitosan. The composite hydrogel system is easy to process, easy to obtain raw materials, and has good safety. It is expected to be transformed into clinical applications in a wide range of fields such as drug delivery and tissue engineering.

The project consists of the State Key Laboratory of Quality Research on Traditional Chinese Medicines, Faculty of Pharmacy, Macau University of Science and Technology, the Sorbonne University in France, the Laboratoire de Chimie de la Matière Condensée de Paris (Laboratoire de Chimie de la Matière Condensée de Paris), and the Institut des Nanosciences. NanoSciences de Paris) was jointly completed by multiple scientific research institutions. Among them, Assistant Professor Wang Xiaolin of Macau University of Science and Technology is the first author of the paper, and Christophe Hélary, a researcher at Sorbonne Université in France, is the corresponding author.

Full text link:

https://doi.org/10.1002/advs.202004213

In order to solve the above-mentioned problems of traditional collagen hydrogels, a research paper entitled "Nanostructured Dense Collagen-Polyester Composite Hydrogels as Amphiphilic Platforms for Drug Delivery" was recently published in the top international journal Advanced Science. This paper innovatively applied the Nanoprecipitation method to the three-dimensional hydrogel network system, and quickly and conveniently prepared the collagen-polyester amphiphilic composite system. The nanoprecipitation process is also called solvent replacement and involves two miscible solvents, one is a good solvent for the polymer (here, THF), and the other is a non-solvent (here, water). During this preparation process, when the collagen gel impregnated with polyester tetrahydrofuran solution comes into contact with PBS, water molecules will diffuse into the polymer chains in the hydrogel, thereby forming solid particles in the 3D dense collagen network. .

Through this method, the paper successfully developed an amphiphilic composite platform that combines high-concentration collagen hydrogel (40 mg/ml) and up to 50 wt% of polyesters with different hydrophobicities and chain lengths. Compared with pure collagen hydrogel, composite materials made of polylactic acid-glycolic acid (PLGA) and polylactic acid (PLA) instead of polycaprolactone (PCL) have higher mechanical properties while maintaining high Hydration. The release kinetics of spironolactone (a lipophilic steroid used as a drug model) can be fine-tuned within a month. Unlike the incorporation of pre-formed micro-nano particles, the new process can not only improve the physical properties of collagen hydrogels, but also control the delivery of drugs. More importantly, this process is also applicable to hydrogel systems such as sodium alginate and chitosan. The composite hydrogel system is easy to process, easy to obtain raw materials, and has good safety. It is expected to be transformed into clinical applications in a wide range of fields such as drug delivery and tissue engineering.

The project consists of the State Key Laboratory of Quality Research on Traditional Chinese Medicines, Faculty of Pharmacy, Macau University of Science and Technology, the Sorbonne University in France, the Laboratoire de Chimie de la Matière Condensée de Paris (Laboratoire de Chimie de la Matière Condensée de Paris), and the Institut des Nanosciences. NanoSciences de Paris) was jointly completed by multiple scientific research institutions. Among them, Assistant Professor Wang Xiaolin of Macau University of Science and Technology is the first author of the paper, and Christophe Hélary, a researcher at Sorbonne Université in France, is the corresponding author.

Full text link:

https://doi.org/10.1002/advs.202004213

18915694570

Previous: Zhang Shubiao/Liang Xi