ACS Appl. Mater. Interfaces: Preparation of Ti3C2Tz-polymer film by Pickering emulsion polymerization and electronic applications

1. Article overview

MXene/polymer composite materials have received extensive attention due to their high electrical conductivity and a wide range of applications such as electromagnetic interference (EMI) shielding, energy storage and catalysis. However, due to the difficulty of dispersing MXenes in common polymers, it is challenging to prepare MXene/polymer composites with high electrical conductivity and satisfactory EMI shielding performance, especially in the case of low MXene loading. This article reports the use of dispersion polymerization to prepare MXene/polymer particles in Pickering emulsions, and proves that these composite powders can be used as raw materials for MXene/polymer composite films with excellent EMI shielding properties. MXene, represented by Ti3c2Tz nanosheets, used three different monomers to prepare armor particles. X-ray photoelectron spectroscopy and scanning electron microscopy confirmed the existence of nanosheets on the particle surface. The armor particles above the polymer Tg are hot pressed to obtain a Ti3C2Tz/polymer composite film; due to the nanosheet network of the particle material template, the film has conductivity. The research in this article provides a new method for preparing MXene/polymer composite films under low MXene loading.

2. Graphic guide

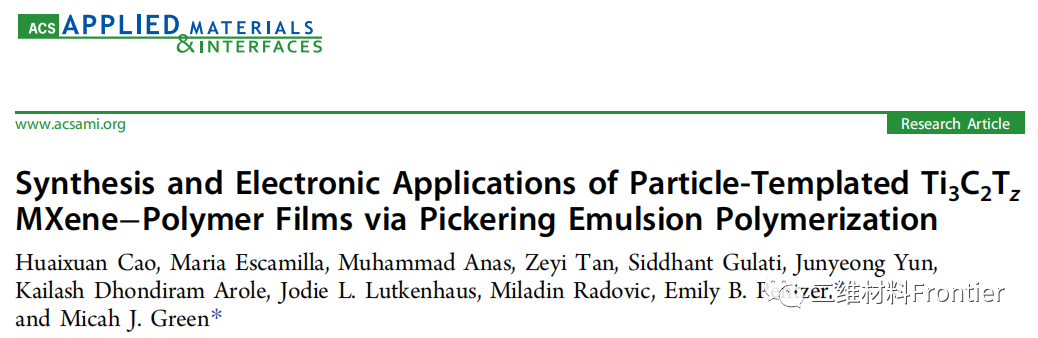

Figure 1. Overview of the preparation method of Ti3C2Tz polymer particles, used to prepare MXene-polymer composite film with high conductivity, rapid radio frequency heating and good electromagnetic shielding performance.

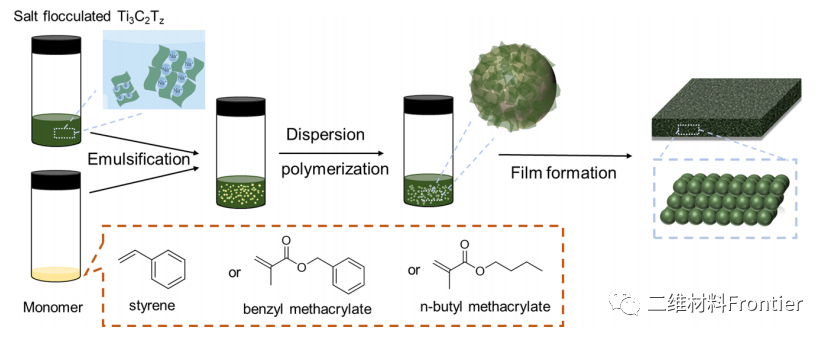

Figure 2. ti3C2Tz nanosheets: (A) XRD of vacuum assisted filtration membrane; (B) TEM of dispersed materials; (C) dispersed AFM (inset shows the thickness of Ti). (D) Scanning electron microscope of Ti3C2Tz freeze-dried sample.

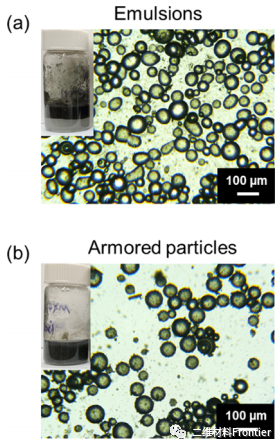

Figure 3. Optical microscope image of Ti3C2/styrene (A) emulsion and (B) armor particles and digital image of the bottle (embedded). The scale bar is 100μm.

Figure 4. Characterization of Ti3c2Tz/PS armor particles: (a, b) SEM images, (c) XPS measurement spectrum and (d) XPS high resolution Ti 2p spectrum.

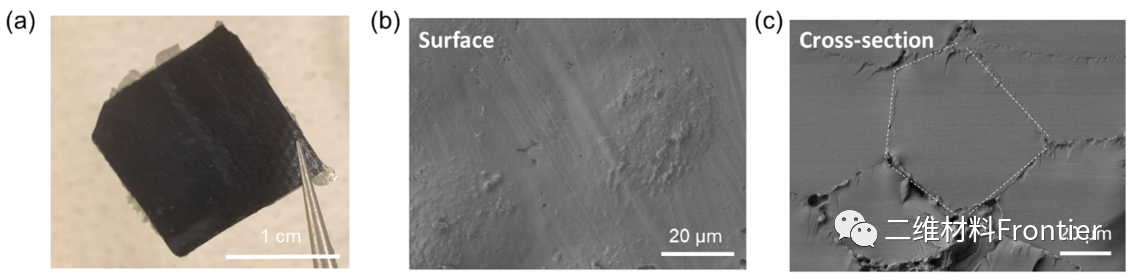

Figure 5. Characterization diagram of Ti3C2Tz/polystyrene composite film.

3. Full text summary

In summary, Ti3C2Tz/ps armor particles were synthesized by dispersion polymerization in Pickering emulsion to prepare a composite film with low Ti3C2Tz load, high conductivity, rapid radio frequency heating speed, and good EMI shielding ability. Nacl is used to flocculate the Ti3C2Tz nanosheets to stabilize the polymerization of the monomer phase in the aqueous monomer emulsion and the droplet monomer phase in the Ti3C2Tz armored polymer particles. The shell structure of the Ti3C2Tz/PS core was verified by SEM, XPS and TGA. The structure of these particles has no significant effect on the Tg of the polymer core. These armor particles were hot-pressed at 110°C to produce a conductive Ti3C2Tz/polymer composite film; scanning electron microscopy characterization showed the circular features of the film surface and cross-section, supporting the formation of a network of Ti3C2Tz nanosheets templated by particles. The chemical structure of the nanosheets was verified by XRD and XPS, indicating the lack of oxidation. The conductivity of Ti3C2Tz/PS film is 0.011S/cm, and it has a rapid radio frequency heating rate (13-15°C/s) in the specific frequency range of 135-150MHz. In addition, these structural composite films with a thickness of 5.19mm have high EMISE and a shielding mechanism dominated by adsorption. The use of other polymers can control the processing temperature. This particle template method for preparing MXene/polymer films can obtain an ordered MXene network in the composite film, and overcome the tendency of nanosheets to aggregate or repackage observed in melt processing and solution blending, thereby reducing MXene enhances electrical performance under load. In addition, this method avoids the use of organic solvents and expands the range of available MXene/polymer compositions for various and customized applications.

Article link:

https://doi.org/10.1021/acsami.1c16234

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

18915694570

Previous: Nano Today: COF grown