Antibacterial Mechanism and Application of Metal Organic Skeleton and its derived Nanomaterials

I. Overview of the article.

Long-term use and overuse of antibiotics lead to the evolution of bacteria to antibiotic resistance. The latest advances in nanotechnology provide new opportunities to overcome the obstacles of antibiotic independence. Metal organic framework (MOF) has become a new tool to combat bacterial infection in the fields of biomedicine and food packaging. This review summarizes the main antibacterial mechanisms of MOF and its derived nanomaterials. The latest progress of MOF and its derived nanomaterials as various antimicrobial agents in biomedical and food packaging were introduced in detail. At the same time, the advantages and disadvantages of MOF in antibacterial applications were put forward.

MOFs is a kind of crystalline porous materials with high surface area, adjustable porosity and flexible skeleton. In recent years MOFs and its derived nanomaterials such as hybrid MOFs MOFs film nano-enzyme and monoatomic nano-enzyme (SAzymes) have attracted wide attention because of their remarkable antibacterial activity. Superior antibacterial properties mainly depend on physical contact, metal ions and ligands, oxidative stress, photothermal effect and synergistic effect. In a variety of forms and antibacterial mechanisms, hybridization and modified MOF show enhanced or targeted control of antibacterial ability, which will be more accurate and optimized in practical application. In addition, the characteristics of easy modification, biocompatibility and biodegradability can promote the application of MOF-based nanomaterials. Although the use of MOFs and its derived nanomaterials as antimicrobial agents is still in its infancy and needs further exploration, it provides a new way and broad prospects in the field of biomedicine and food packaging.

Second, guided reading of picture and text.

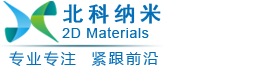

Figure 1.

Antibacterial mechanism of nanomaterials derived from MOFs and MOF. (a) the physical damage of positively charged ZIF nano-dagger array to bacterial cells. (B) Metal ions and ligands released during MOFs degradation are used for sterilization. (C) hydrazinobenzoate joint of zinc-based MOF responsible for antibacterial activity. (d) the active site of Cu-MOFs used to inactivate bacteria. (e) Porphyrin SURGEL film combined with aPDT killed bacteria. (F) MOF/Ag-based hybrid nanomaterials for synergistic sterilization.

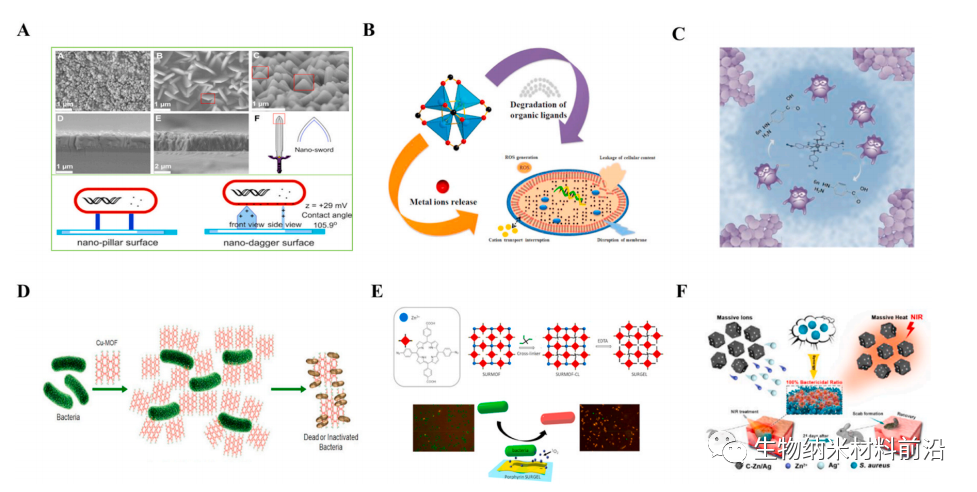

Figure 2.

Biological MOF used for antimicrobial activity. (a) preparation of GS5-CL-Ag@CD MOF for antibacterial and wound healing applications. (B) preparation of HKUST-1/OCB and ZIF-8/OCB based on biodegradable cellulose for dye adsorption and antibacterial applications.

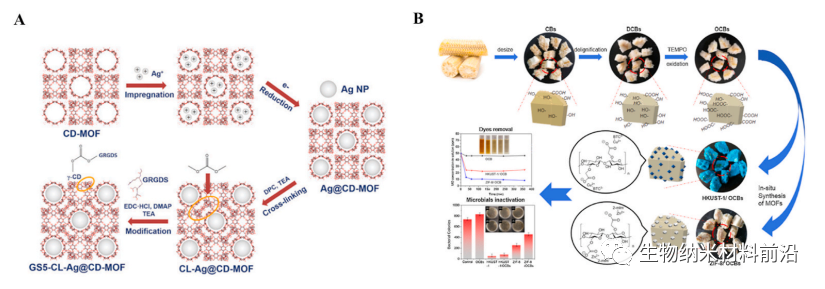

Figure 3.

MOF-based membrane for antibacterial applications. (a) Synthesis of ZIF-8/PDA/PS composite membrane for antibacterial applications. (B) prepare HKUST-CS films for antibacterial and wound dressings. (C) Zirconium-based MOF/ poly (ε-caprolactone) mixed matrix membrane (MMM) was synthesized as an effective antibacterial agent. (d) MOF/Poly (ε-caprolactone) electrospun nanofiber membrane for antibacterial applications.

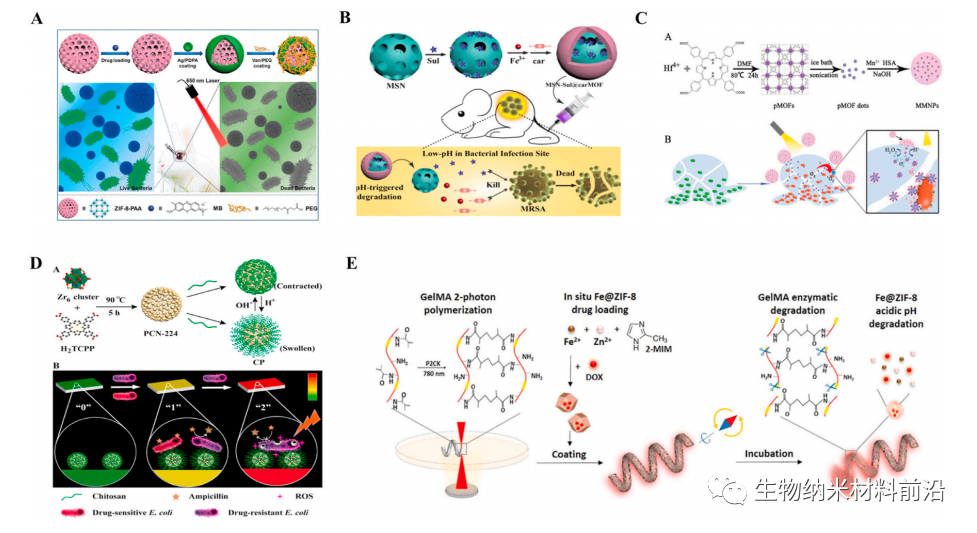

Figure 4.

MOFs is used as the carrier of different antimicrobial agents. (a) to construct ZIF-8-PAA-MB@AgNPs@Van-PEG composite nanomaterials with synergistic chemotherapy and PDT effect for antibacterial applications. (B) pH responds to automotive / Fe3+ MOF coated MSN loaded with antibiotics and β-lactamase inhibitors to fight MRSA. (C) pH/H2O2 responds to the synthesis of antimicrobial systems. MnO2 coated with HAS encapsulates pMOF sites and applies it to eradicate bacterial biofilms. (d) instructions for detection of paper-based acid care sites and elimination of target bacteria for drug-resistant Escherichia coli with antibiotic-based chemotherapy and MOF-based aPDT. (e) description of biodegradable MOFBOT used to encapsulate DOX@Fe@ZIF-8.

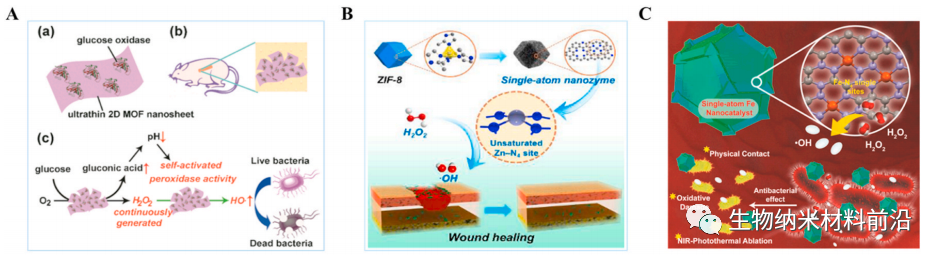

Figure 5.

MOF is used as a nano-enzyme and a monoatomic nano-enzyme derived from MOF for antibacterial applications. (a) A diagram of two-dimensional MOF/GOx mixed nanocatalysts for antibacterial applications. (B) Zn-N-C monoatomic nanoenzyme derived from ZIF-8 was used in wound antibacterial application. (C) Monoatomic iron nanocatalysts (SAF NCs) for antibacterial applications.

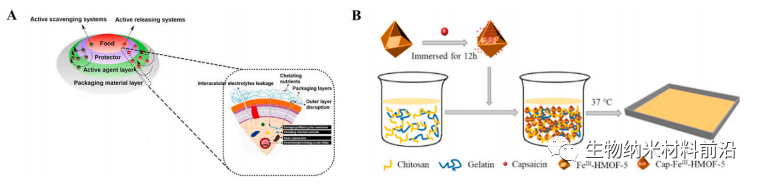

Figure 6.

Antibacterial application of MOFs in food packaging. (a) the antibacterial mechanism of biodegradable packaging layer combined with antimicrobial agents. (B) Synthesis of FeIII-HMOF-5 modified gel / chi film for antibacterial food packaging applications.

III. Summary of the full text.

Anti-antibiotics, which aggravates the threat. Therefore, it is of great significance and urgent to explore new antibacterial strategies to protect human beings from bacterial infection. The development of nanotechnology provides an alternative way to overcome the current antibacterial obstacles. MOFs is a new hybrid nanomaterial with metal ions and organic ligands, which has obvious physical and chemical properties, such as high surface area, adjustable porous size and flexible skeleton. MOFs has attracted wide attention because of its high antibacterial activity. In addition, good biocompatibility and biodegradability make MOF an ideal material for biological applications. The easy functionalization of MOFs can produce many nanocomposites with excellent properties, which promote antibacterial applications through synergism. The main antibacterial mechanisms of MOFs and MOF derived nanomaterials can be divided into physical contact, metal ions and ligands sterilization, oxidative stress, photothermal effect and synergistic effect. A large number of MOFs and MOF-based materials have been explored as antimicrobial biomedical and food packaging agents in a variety of forms, such as separate MOF, mixed MOF, MOF film, MOF as an antibacterial delivery carrier, nano-enzyme and MOF-derived SAzyme. Although some impressive progress has been made in MOF-based materials for antimicrobial applications, some challenges and obstacles to further research should be considered.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.

18915694570

Previous: The MXene hydrogel was