Zhejiang University Science: realize the preparation of bionic artificial teeth!

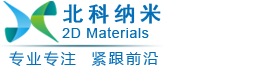

Recently, researcher Liu Zhaoming and Professor Tang Ruikang from the Department of chemistry of Zhejiang University published an article entitled pressure driven fusion of amorphous particles into integrated monoliths in the world s top scientific journal Science. Inspired by nature, the research team, To create a bionic calcium carbonate tooth. . By adjusting the structural water content and external pressure, they successfully fused hundreds of nano-sized amorphous calcium carbonate particles into millimeter scale macro block materials with continuous structure. The block is transparent, and its mechanical properties are similar to those of single crystal calcite.

Professor Tang Ruikang, Department of chemistry, Zhejiang University, cooperated with researcher Liu Zhaoming in the latest research and found that the fusion of amorphous calcium carbonate particles can be realized by adjusting the internal structure, water content and external pressure of amorphous calcium carbonate particles. This strategy of using the structural characteristics of materials to promote mass transfer overcomes the shortcomings of traditional sintering and provides a new method for the preparation of inorganic bulk materials, In particular, it provides an important preparation strategy. According to this method, the broken mirror can really be reunited as it appears.

Several stones merge into one stone

The previous achievement of Tang Ruikang s team - inorganic ion polymerization can realize the rapid preparation of centimeter sized calcium carbonate crystal materials in the laboratory, and the preparation process of these calcium carbonate has strong plasticity, which can grow into various shapes according to the mold shape just like plastic, The study was published in the top international journal Nature in October 2019“ The research in 2019 is to synthesize calcium carbonate crystal bulk materials from scratch. Our work is to study how to turn the existing calcium carbonate powder materials into bulk materials, such as fusing several stones into a big stone. It can be said that the two tasks come to the same end by different routes. Tang Ruikang said. It is in the research process of the previous work that Mu Zhao found an interesting phenomenon that the boundary of amorphous calcium carbonate particles gradually disappeared during the pressing process, and finally completely fused into one. At that time, Mu Zhao did not understand the reasons behind the phenomenon, but Tang Ruikang encouraged Mu Zhao to continue to dig deeper and ask more why. It turns out that water molecules play an important role in the crystallization of amorphous calcium carbonate particles. Although scientists have noticed this phenomenon before, there is still a lack of in-depth study on the relationship between the function, fluidity and structural stability of structural water. Mu Zhaohe and Kong kangren further found that if the water molecules can be kept at a suitable amount, a dynamic water channel can be formed in calcium carbonate, thus promoting the internal material transport process and eventually leading to the fusion of amorphous particles“ Too much water will form a new kind of water cluster, leading to the crystallization of amorphous calcium carbonate particles When one calcium carbonate molecule corresponds to 0.2-1.1 water molecule, and then 0.6-3.0 GPA pressure is applied, the fusion of amorphous calcium carbonate particles under pressure can be realized. The team has successfully constructed calcium carbonate bulk materials with continuous structure. In order to verify the results, the team labeled the gold nanoparticles on the surface of calcium carbonate particles. After extrusion, it was observed by high-resolution transmission electron microscope that there was no interface or gap between the calcium carbonate particles, and it was indeed completely fused“ Stone is rigid, and water is flexible. When there is a proper amount of structural water in the stone, the stone is like plasticine under pressure. When it is extruded, it will fuse and reach the state of you have me, I have you. Liu Zhaoming said.

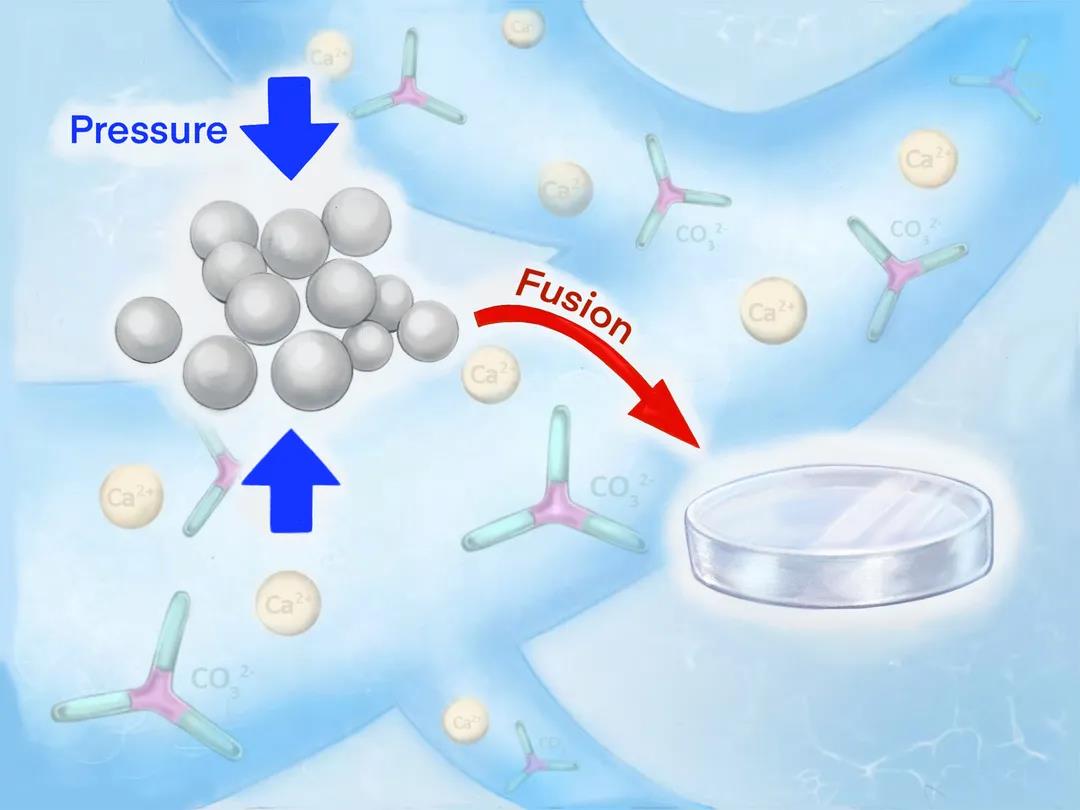

Upper left: the schematic diagram of water clusters, in which there are water channels (dark purple) formed by water molecules; Top right: comparison of mechanical properties of bulk materials. The illustration shows comparison of optical transmittance of bulk materials formed by unfused and fully fused particles; Below: with the increase of pressure, the particles gradually change from non fusion to complete fusion.

A new way of material synthesis

Due to the continuous structure of the new preparation mode, the optical transmittance and mechanical properties of calcium carbonate bulk materials are very good, with hardness of 2.739 GPA and elastic modulus of 49.672 GPa. These properties are better than most cement-based bulk materials, and even close to the properties of calcite single crystal. And this method does not need high temperature, so the preparation is relatively fast and convenient“ If the required pressure can be reduced in the future, it will be closer to practical application. Kong kangren said. The work helps us better understand and mimic biomineralization, Tang said. For example, one of the top predators in the deep sea, the formation of transparent teeth of arowana: the high-pressure environment in the deep sea and amorphous minerals all imply the formation conditions of teeth with continuous structure. At the same time, the discovery of dynamic water channel in the study proposed a new possible way of material existence: liquid like. In our general understanding, solid is solid and liquid is liquid. There is a clear distinction between the two. But in the future, there may be an intermediate state between solid and liquid“ We further found that the fusion phenomenon is suitable for a variety of inorganic ionic compounds. Besides water molecules, other ions can also be added as additives, which will affect the fluidity and fusibility of calcium carbonate. This fully demonstrates the potential methods to improve the fluidity of solid materials, and puts forward a new cognition for the fusion of solid materials, which is expected to make solid inorganic materials have the properties similar to liquid at room temperature. This research shows the advantages of amorphous phase in material processing, and gives artificial bulk materials a new preparation mode, which is expected to be applied in the fields of biology, medicine, materials and so on. The paper review experts believe: this novel and innovative research has potential leading significance for the design of new ceramics and ceramic / organic composites, and has important value for improving the mechanical properties of materials, especially for thermal sensitive materials.

This information is from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately

18915694570

Previous: When novananoenzymes m

Next: Nature communications