After Nature, AM will be released again! UCLA He Ximin team: adjustable sponge-like hierarchical pore structure hydrogel with enhanced diffusivity and mechanical properties

Cross-linked polymers and gels have a wide range of applications in soft robotics, solar steam generation, energy storage, drug delivery, catalysis, and biosensing due to their softness, simple and adjustable synthesis characteristics. However, their attractive mass transfer and volume change capabilities are limited by diffusion. The responsivity of smart hydrogels is inversely proportional to the square of the minimum size of the hydrogels, and miniaturized designs are required to avoid slow response. At present, researchers mostly improve the diffusion of hydrogels by increasing porosity or restricting pores by orientation. However, the above methods will greatly compromise the mechanical properties, such as Youngs modulus and toughness. Hydrogels with too high porosity often lack the necessary rigidity in practical applications. Despite the tremendous efforts of researchers, it is still a long-standing challenge to enhance the diffusion and mechanical properties of hydrogels at the same time, which hinders the practical application of hydrogels.

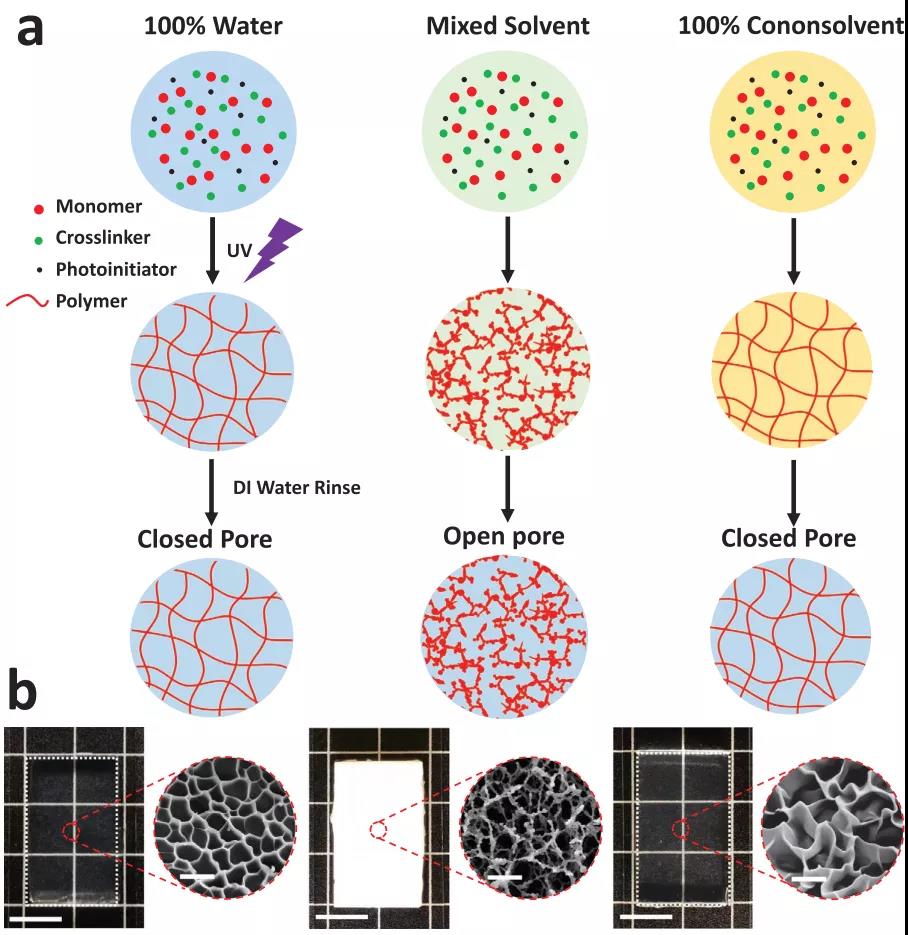

In order to solve the above problems, He Ximins team proposed a co-solvent photopolymerization method to prepare sponge-like mesoporous hydrogels, which also enhanced swelling and mechanical properties, as shown in the schematic diagram.

Scheme 1. a) Schematic diagram of mixed solvent photopolymerization technology. b) Optical photographs and SEM images of photopolymerization of PNIPAM hydrogel in 0 mol%, 40 mol% and 100 mol% DMSO.

The prepared poly(isopropylacrylamide) hydrogel has a unique open porous network with continuous microchannels, resulting in a record high volume expansion rate, which is almost an order of magnitude higher than previously reported. Compared with traditional hydrogels prepared with pure solvents, this swelling enhancement is accompanied by an increase in Youngs modulus and toughness. They systematically studied the influence of solvent composition and reaction temperature on the microstructure, mechanical properties and swelling properties of hydrogels. Furthermore, a 3D printable PNIPAM hydrogel has been developed to have widely adjustable swelling and mechanical properties, and this principle is extended to other polymer hydrogel systems.

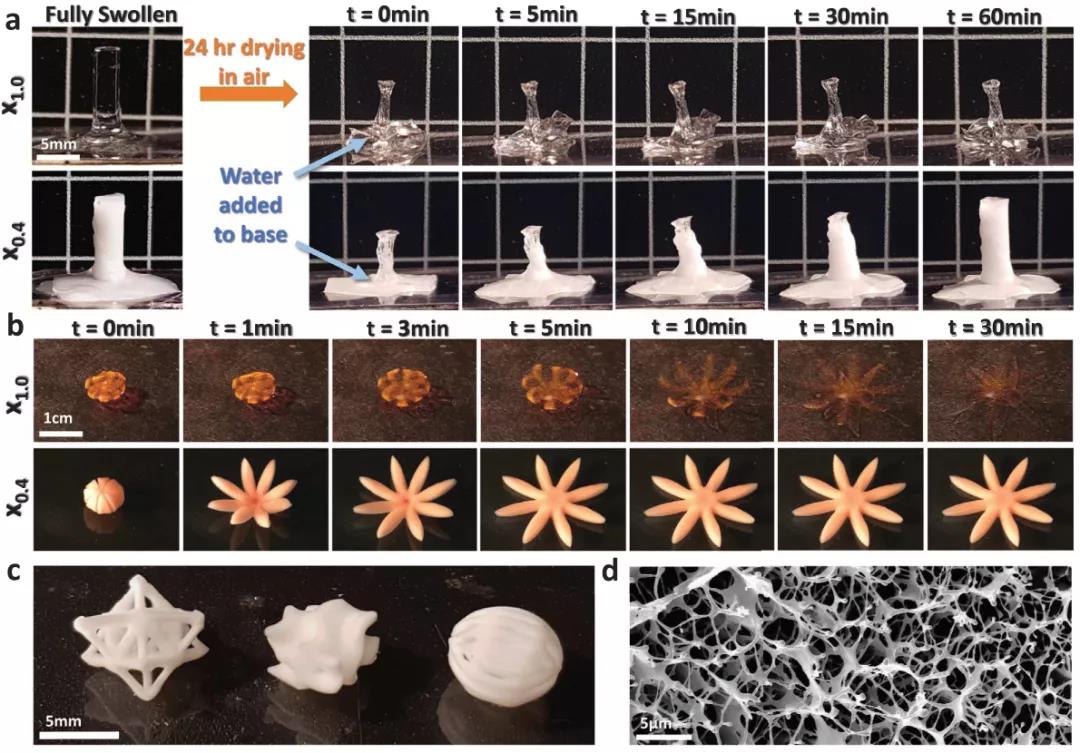

This method is compatible with 3D printing. By extending this technology to non-temperature-responsive polymer systems such as poly-tert-butylacrylamide-co-polyacrylamide and polyacrylamide hydrogel, it is proved that conconsolvency is a universal phenomenon driven by competitive adsorption.

Figure 1 a) Air swelling behavior of x1.0 and x0.4 gel columns; b-c) 3D printed hydrogel structure; d) SEM picture of 3D printed PNIPAM.

Conclusion: This hydrogel delivery system can achieve the synergistic release of immune adjuvants and chemotherapeutics or radiotherapy, and can be used repeatedly and at low individual doses for a long time, thereby greatly improving the efficacy of its anti-tumor therapy. This strategy is highly consistent with the low-dose repeated treatment of chemotherapy or radiotherapy in a clinical treatment process, and it has great potential for clinical transformation.

18915694570

Previous: Bai Feng, Henan Univer