Xian Jiaotong University Tang Jingda/Harvard Suo Zhigang

The pros and cons of mechanical properties are the key factors that determine the application of hydrogels. Since 2003, researchers have successively adopted strategies such as dual networks to achieve high modulus, high strength, and high fracture toughness of hydrogels. In recent years, it has been found that the fatigue performance of high-strength hydrogels is poor, which restricts its further development. The difference is that natural biological tissues (heart valves, tendons, vocal cords, etc.) often have complex shapes and good anti-fatigue properties. For example, heart valves need to be opened and closed billions of times in a persons life without damage. . Therefore, how to simulate biological tissues to develop anti-fatigue hydrogels has become the focus of attention in the field.

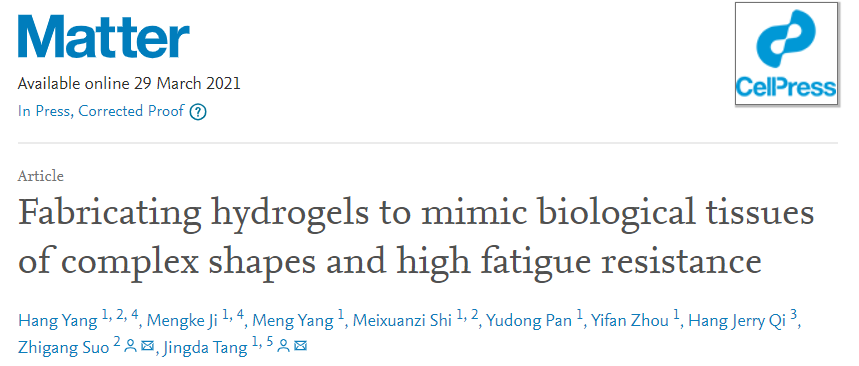

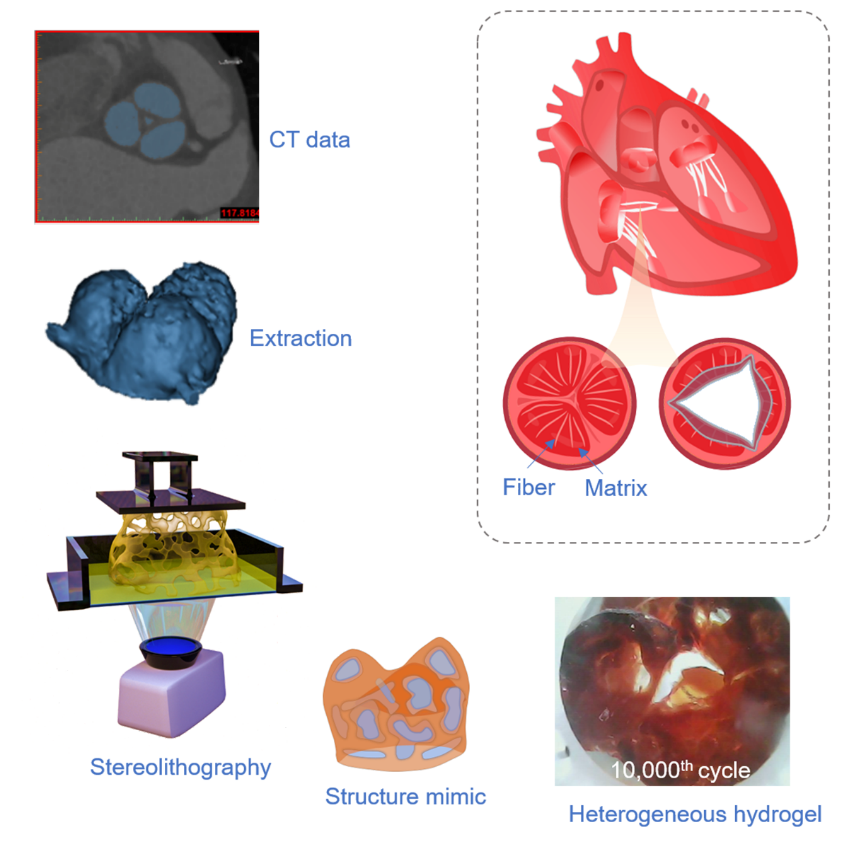

Recently, Associate Professor Tang Jingda of the School of Aeronautics and Astronautics of Xian Jiaotong University collaborated with Academician Zhigang Suo of Harvard University to simulate the heterogeneous structure of biological heart valves, using digital light-curing printing technology to prepare a two-phase composite hydrogel. The complex shape and high fatigue threshold of hydrogel materials. The researchers designed a composite hydrogel composed of a hard skeleton and a soft matrix. Both components are stretchable hydrogel materials with significant modulus differences and a strong topological bond at the interface. The fatigue threshold of the composite hydrogel is as high as 441 J/m2. The researchers further used medical CT images to make a composite hydrogel in the shape of a heart valve, and designed an in vitro test system that simulates blood circulation. The results showed that the homogeneous hydrogel was destroyed rapidly after 560 cycles, while the composite hydrogel remained intact after 10,000 cycles. This research solves the long-standing problems of hydrogel materials and provides broad prospects for its biomedical applications. Researchers hope that in the future, they can develop a hydrogel heart valve that meets both mechanical properties and biocompatibility requirements.

The research results were published in the sister journal Matter of the top international journal Cell. The first author of the thesis is Yang Hang, a graduate student of the School of Aeronautics and Astronautics of Xian Jiaotong University (now a PhD candidate at Harvard University), the co-first author is a graduate student Ji Mengke, and the corresponding authors are Associate Professor Tang Jingda of Xian Jiaotong University and Professor Zhigang Suo of Harvard University. Professor Qi Hang from Georgia Institute of Technology is the co-author of the paper. The State Key Laboratory of Mechanical Structure Strength and Vibration of Xian Jiaotong University is the first signature and first communication unit of the paper.

This research work was funded by the National Natural Science Foundation of Chinas key international (regional) cooperative research projects, youth projects, and post-doctoral innovative talent support programs.

Associate Professor Tang Jingda joined the School of Aeronautics and Astronautics of Xian Jiaotong University in 2017. He has carried out research in the field of soft matter mechanics and published more than 20 papers, of which the first/corresponding author was published in Adv. Funct. Mater., J. Mech. Phys. Solids, ACS Appl. Mater. Interfaces and other journals.

Article link:

https://www.sciencedirect.com/science/article/pii/S2590238521001181?dgcid=author

Recently, Associate Professor Tang Jingda of the School of Aeronautics and Astronautics of Xian Jiaotong University collaborated with Academician Zhigang Suo of Harvard University to simulate the heterogeneous structure of biological heart valves, using digital light-curing printing technology to prepare a two-phase composite hydrogel. The complex shape and high fatigue threshold of hydrogel materials. The researchers designed a composite hydrogel composed of a hard skeleton and a soft matrix. Both components are stretchable hydrogel materials with significant modulus differences and a strong topological bond at the interface. The fatigue threshold of the composite hydrogel is as high as 441 J/m2. The researchers further used medical CT images to make a composite hydrogel in the shape of a heart valve, and designed an in vitro test system that simulates blood circulation. The results showed that the homogeneous hydrogel was destroyed rapidly after 560 cycles, while the composite hydrogel remained intact after 10,000 cycles. This research solves the long-standing problems of hydrogel materials and provides broad prospects for its biomedical applications. Researchers hope that in the future, they can develop a hydrogel heart valve that meets both mechanical properties and biocompatibility requirements.

The research results were published in the sister journal Matter of the top international journal Cell. The first author of the thesis is Yang Hang, a graduate student of the School of Aeronautics and Astronautics of Xian Jiaotong University (now a PhD candidate at Harvard University), the co-first author is a graduate student Ji Mengke, and the corresponding authors are Associate Professor Tang Jingda of Xian Jiaotong University and Professor Zhigang Suo of Harvard University. Professor Qi Hang from Georgia Institute of Technology is the co-author of the paper. The State Key Laboratory of Mechanical Structure Strength and Vibration of Xian Jiaotong University is the first signature and first communication unit of the paper.

This research work was funded by the National Natural Science Foundation of Chinas key international (regional) cooperative research projects, youth projects, and post-doctoral innovative talent support programs.

Associate Professor Tang Jingda joined the School of Aeronautics and Astronautics of Xian Jiaotong University in 2017. He has carried out research in the field of soft matter mechanics and published more than 20 papers, of which the first/corresponding author was published in Adv. Funct. Mater., J. Mech. Phys. Solids, ACS Appl. Mater. Interfaces and other journals.

Article link:

https://www.sciencedirect.com/science/article/pii/S2590238521001181?dgcid=author

18915694570

Previous: Dual-network hydrogel