In the case of natural growth, embryonic development and tissue healing require high concentrations of cells and complex structural and organizational changes to form the final tissue morphology and structure.

Tissue engineering can make cells or tissues grow in a prescribed shape, and build tissues and organs in vivo or in vitro. For example, implanting cells that produce cartilage and skin tissue in an ear-shaped stent may eventually form a transplantable ear. At present, the stents used in this process can be roughly divided into two categories: metal materials and biodegradable materials.

However, whether it is a geometric static scaffold made of metal or degradable materials, there is another problem in practical applications: the formed tissue cannot dynamically change shape, which makes it unable to interact with dynamically changing adjacent tissues.

In order to solve this problem, researchers at the University of Illinois at Chicago (UIC) have developed a new type of 4D hydrogel material, which can change shape under psychological stimulation, and may become the production of bioengineered tissues and organs in the future. Next-generation materials.

A paper related to this research was published in Advanced Functional Materials on February 24, entitled "Induction of Four-Dimensional Spatiotemporal Geometric Transformations in High Cell Density" (Induction of Four-Dimensional Spatiotemporal Geometric Transformations in High Cell Density). Tissues via Shape-Changing Hydrogels).

The material can be rolled into a tube under the action of water. This property will help it be used to make bioengineered blood vessels and other tubular tissue structures. It was developed by a research team led by UIC biomedical engineering professors Eben Alsberg and Richard.

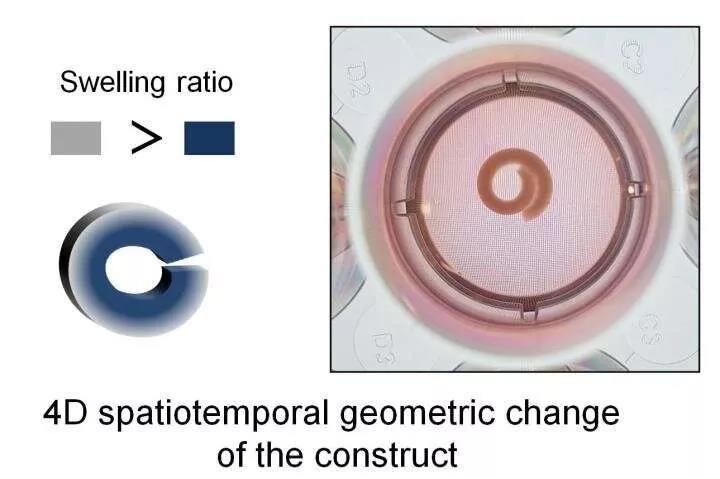

4D materials are similar to 3D materials, but the difference between the two is that 4D materials can achieve dynamic changes in shape in a specific environment (such as water, light, etc.). In other words, 4D materials are 3D materials that can undergo geometric changes.

4D hydrogel that changes shape in water

In fact, previous bioengineering researchers have regarded 4D materials as potential materials for tissue engineering structure manufacturing, but there are still problems that cannot be degraded and are compatible with cells, which limit its application in regenerative medicine. To apply this advantage to bioengineering, the Alsberg research team developed a new type of biodegradable 4D material based on gelatin hydrogel that can change shape with the increase of water and is compatible with cells. It is reported that the hydrogel also supports a very high cell density, and therefore can be shaped with cells.

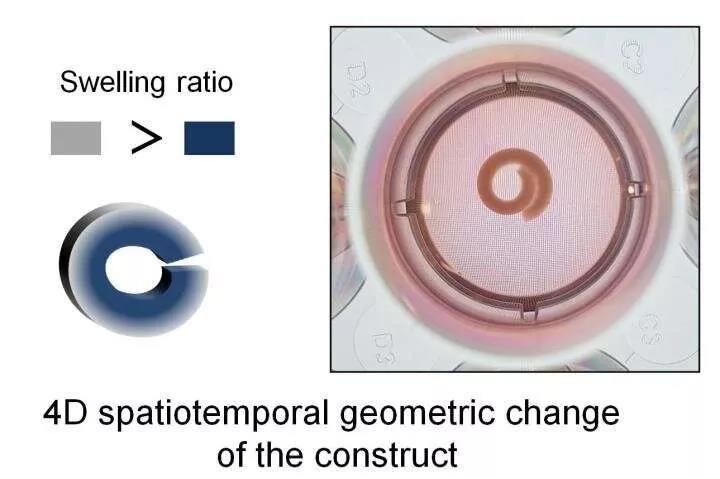

The researchers mentioned in the paper that the degree of hydrogel swelling can be adjusted by changing the degradation rate of the material, the degree of polymer crosslinking and the concentration. In this experiment, the researchers used oxidized alginate methacrylate (OMA) and methacrylate esterified gelatin (Gel MA) to cross-link to form this 4D hydrogel material, which can be achieved without external stimuli. Controllable shape changes.

After their research, they found that the higher the polymer concentration and the degree of cross-linking, the smaller and slower the degree of deformation induced by water absorption of the hydrogel. Based on this, the researchers put hydrogels with different water absorption properties in water like a stack of paper, and the whole material will bend into a "C"-shaped structure. If it is bent enough, it will be able to form a structure similar to blood vessels or other tubular organs.

They also found that the system can be calibrated by controlling the degree of shape change and the time required for the hydrogel. They also used experiments to verify that bone marrow stem cells were embedded in the hydrogel at a very high density and kept the cells viable.

In the paper, the researchers also described how to turn the cell-filled hydrogel into bone and cartilage-like tissue, and use the material to obtain complex biological structures through 4D printing.

The research seems to be able to solve the problems of metal stents and traditional biodegradable bio-stents, but it is not yet known whether it will be applied in practice. In any case, it is very meaningful in the practical application of bioengineering.

Paper link:

https://medicalxpress.com/news/2021-02-shape-changing-4d-materials-morphodynamic-tissue.html

https://onlinelibrary.wiley.com/doi/10.1002/adfm.202010104

Tissue engineering can make cells or tissues grow in a prescribed shape, and build tissues and organs in vivo or in vitro. For example, implanting cells that produce cartilage and skin tissue in an ear-shaped stent may eventually form a transplantable ear. At present, the stents used in this process can be roughly divided into two categories: metal materials and biodegradable materials.

However, whether it is a geometric static scaffold made of metal or degradable materials, there is another problem in practical applications: the formed tissue cannot dynamically change shape, which makes it unable to interact with dynamically changing adjacent tissues.

In order to solve this problem, researchers at the University of Illinois at Chicago (UIC) have developed a new type of 4D hydrogel material, which can change shape under psychological stimulation, and may become the production of bioengineered tissues and organs in the future. Next-generation materials.

A paper related to this research was published in Advanced Functional Materials on February 24, entitled "Induction of Four-Dimensional Spatiotemporal Geometric Transformations in High Cell Density" (Induction of Four-Dimensional Spatiotemporal Geometric Transformations in High Cell Density). Tissues via Shape-Changing Hydrogels).

The material can be rolled into a tube under the action of water. This property will help it be used to make bioengineered blood vessels and other tubular tissue structures. It was developed by a research team led by UIC biomedical engineering professors Eben Alsberg and Richard.

4D materials are similar to 3D materials, but the difference between the two is that 4D materials can achieve dynamic changes in shape in a specific environment (such as water, light, etc.). In other words, 4D materials are 3D materials that can undergo geometric changes.

4D hydrogel that changes shape in water

In fact, previous bioengineering researchers have regarded 4D materials as potential materials for tissue engineering structure manufacturing, but there are still problems that cannot be degraded and are compatible with cells, which limit its application in regenerative medicine. To apply this advantage to bioengineering, the Alsberg research team developed a new type of biodegradable 4D material based on gelatin hydrogel that can change shape with the increase of water and is compatible with cells. It is reported that the hydrogel also supports a very high cell density, and therefore can be shaped with cells.

The researchers mentioned in the paper that the degree of hydrogel swelling can be adjusted by changing the degradation rate of the material, the degree of polymer crosslinking and the concentration. In this experiment, the researchers used oxidized alginate methacrylate (OMA) and methacrylate esterified gelatin (Gel MA) to cross-link to form this 4D hydrogel material, which can be achieved without external stimuli. Controllable shape changes.

After their research, they found that the higher the polymer concentration and the degree of cross-linking, the smaller and slower the degree of deformation induced by water absorption of the hydrogel. Based on this, the researchers put hydrogels with different water absorption properties in water like a stack of paper, and the whole material will bend into a "C"-shaped structure. If it is bent enough, it will be able to form a structure similar to blood vessels or other tubular organs.

They also found that the system can be calibrated by controlling the degree of shape change and the time required for the hydrogel. They also used experiments to verify that bone marrow stem cells were embedded in the hydrogel at a very high density and kept the cells viable.

In the paper, the researchers also described how to turn the cell-filled hydrogel into bone and cartilage-like tissue, and use the material to obtain complex biological structures through 4D printing.

The research seems to be able to solve the problems of metal stents and traditional biodegradable bio-stents, but it is not yet known whether it will be applied in practice. In any case, it is very meaningful in the practical application of bioengineering.

Paper link:

https://medicalxpress.com/news/2021-02-shape-changing-4d-materials-morphodynamic-tissue.html

https://onlinelibrary.wiley.com/doi/10.1002/adfm.202010104

18915694570

Previous: Tang Jianbin Nano Lett