Bio 3D printing using universal orthogonal network biohydrogel

Biological 3D printing technology is a kind of potential tissue-like structure manufacturing technology, but the lack of diversity of bio-inks is a major factor limiting its development. In order to meet this demand for a universally applicable bio-ink strategy, the team of Professor Sarah C. Heilshorn of Stanford University has developed a universal bio-orthogonal bio-ink cross-linking mechanism, which is compatible with cells and with a series of polymers Achieve cross-linking, and published an article titled "3D Bioprinting using UNIversal Orthogonal Network (UNION) Bioinks" in Advanced Functional Materials magazine, prepared with gelatin, hyaluronic acid (HA), recombinant elastin-like protein (ELP) and Polyethylene glycol (PEG) as the main polymer of the general orthogonal network (joint) bio-ink. And its printability, mechanical properties, diffusion coefficient, etc. were characterized. And use general orthogonal hydrogel to load matrix adherent human corneal mesenchymal stromal cells and non-matrix adherent human induced pluripotent stem cells for printing experiments. After printing, the cells still maintain high viability and express characteristic phenotypic markers.

The lack of types of biological materials is the biggest obstacle restricting the development of biological 3D printing technology. As the cell phenotype is very sensitive to the biochemical and mechanical properties of the surrounding environment, the matrix properties provided by bio-inks will become more and more important for cell diversification. Ideally, each cell type can match its own bio-ink matrix characteristics, so that the bio-ink can be customized according to the cell and structural requirements of the desired tissue application. Due to the limited number of bio-inks currently available, there is clearly a need for a general bio-ink strategy that can be easily customized to support any type of cell. However, the current number of cross-linking strategies for hydrogel materials is limited, which ultimately leads to the lack of diversity of bio-inks.

In order to achieve greater diversity of bio-inks, new cross-linking strategies are needed. In order to prevent the bio-ink from producing biochemical stimuli that are not conducive to cell survival during the molding process. The general bio-ink family developed must meet the following conditions: (1) Use cell-compatible and applicable multiple polymer cross-linking methods; (2) Polymerize to form macromolecular structures; (3) Can be used for multiple support baths; 4) Biochemical and mechanical properties can be customized for a variety of cell types.

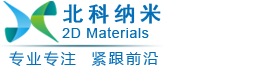

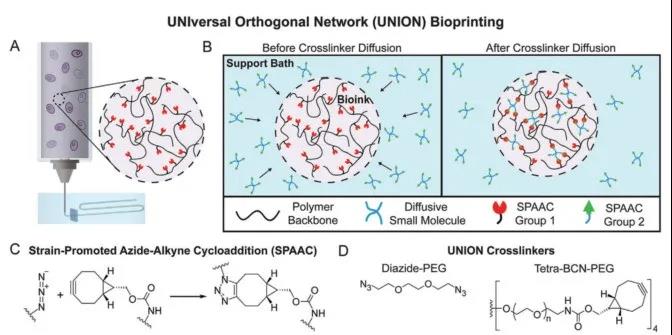

The preparation of the universal orthogonal bio-ink is to graft the bio-orthogonal chemical group to the main chain of the hydrogel material through the SPAAC reaction, and modify the complementary bio-orthogonal chemical group to the crosslinker molecule. By controlling the diffusion of the cross-linking agent molecules into the bio-ink, the SPAAC cross-linking reaction occurs, and the cross-linking and curing of the hydrogel material is realized.

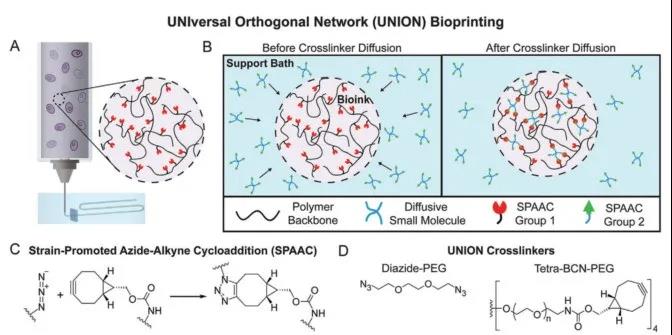

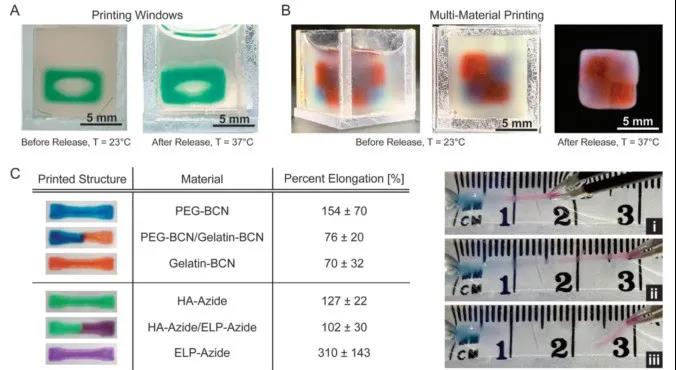

The article mainly uses a gel suspension bath for printing. The shear-thinning gel support material is mixed with a cross-linking agent. The extrusion nozzle extends into the bio-ink extruded below the liquid surface to construct a 3D structure. At the same time, the cross-linking agent is small. The molecules begin to diffuse into the bio-ink, and the SPAAC reaction occurs at the same time, and finally solidifies through cross-linking to obtain a complete three-dimensional solid hydrogel structure. The article uses this method to print window structure, multi-material square and multi-material tensile structure.

Since this type of bio-ink uses the same bio-orthogonal chemical method and the same cross-linking agent, a variety of bio-inks can be cross-linked in the same way, as long as they are all grafted with the same bio-orthogonal group. In this way, multiple polymer materials can be mixed together to create an infinite bio-ink library with different polymer compositions for further customization.

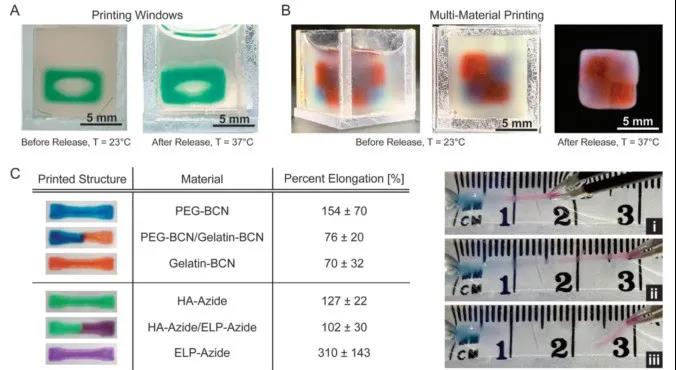

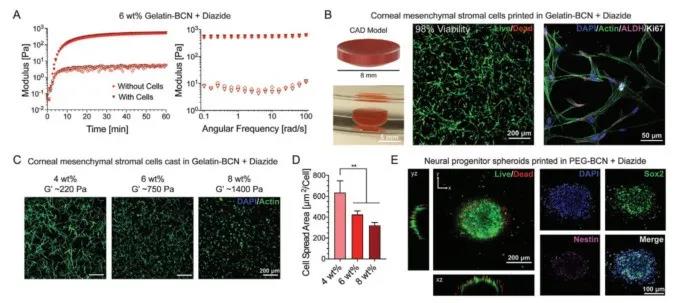

In addition, the key to the adaptability of the universal bio-ink system is its customization ability to match the required bioprinting application. Therefore, the researchers also constructed cell culture scaffolds based on the matrix mechanical properties of different cell types, verifying that corneal stromal cells, neural precursor cells, etc. still maintain good viability and functional expression in the bio-ink material. Prove that the bio-orthogonal cross-linked bio-ink does not cross-react with other bio-molecules, including bio-molecules that exist on the cell surface, the culture medium or the ink itself, which makes it a universal strategy.

In summary, the joint bio-ink strategy serves as a universal bio-ink platform. This strategy may realize multi-material and multi-cell bioprinting, mimic the structure of the body, and may enhance the transformation and therapeutic potential of 3D bioprinting technology.

Information source: EngineeringForLife

This information is from the Internet for academic exchanges. If there is any infringement, please contact us and delete it immediately

The lack of types of biological materials is the biggest obstacle restricting the development of biological 3D printing technology. As the cell phenotype is very sensitive to the biochemical and mechanical properties of the surrounding environment, the matrix properties provided by bio-inks will become more and more important for cell diversification. Ideally, each cell type can match its own bio-ink matrix characteristics, so that the bio-ink can be customized according to the cell and structural requirements of the desired tissue application. Due to the limited number of bio-inks currently available, there is clearly a need for a general bio-ink strategy that can be easily customized to support any type of cell. However, the current number of cross-linking strategies for hydrogel materials is limited, which ultimately leads to the lack of diversity of bio-inks.

In order to achieve greater diversity of bio-inks, new cross-linking strategies are needed. In order to prevent the bio-ink from producing biochemical stimuli that are not conducive to cell survival during the molding process. The general bio-ink family developed must meet the following conditions: (1) Use cell-compatible and applicable multiple polymer cross-linking methods; (2) Polymerize to form macromolecular structures; (3) Can be used for multiple support baths; 4) Biochemical and mechanical properties can be customized for a variety of cell types.

The preparation of the universal orthogonal bio-ink is to graft the bio-orthogonal chemical group to the main chain of the hydrogel material through the SPAAC reaction, and modify the complementary bio-orthogonal chemical group to the crosslinker molecule. By controlling the diffusion of the cross-linking agent molecules into the bio-ink, the SPAAC cross-linking reaction occurs, and the cross-linking and curing of the hydrogel material is realized.

The article mainly uses a gel suspension bath for printing. The shear-thinning gel support material is mixed with a cross-linking agent. The extrusion nozzle extends into the bio-ink extruded below the liquid surface to construct a 3D structure. At the same time, the cross-linking agent is small. The molecules begin to diffuse into the bio-ink, and the SPAAC reaction occurs at the same time, and finally solidifies through cross-linking to obtain a complete three-dimensional solid hydrogel structure. The article uses this method to print window structure, multi-material square and multi-material tensile structure.

Since this type of bio-ink uses the same bio-orthogonal chemical method and the same cross-linking agent, a variety of bio-inks can be cross-linked in the same way, as long as they are all grafted with the same bio-orthogonal group. In this way, multiple polymer materials can be mixed together to create an infinite bio-ink library with different polymer compositions for further customization.

In addition, the key to the adaptability of the universal bio-ink system is its customization ability to match the required bioprinting application. Therefore, the researchers also constructed cell culture scaffolds based on the matrix mechanical properties of different cell types, verifying that corneal stromal cells, neural precursor cells, etc. still maintain good viability and functional expression in the bio-ink material. Prove that the bio-orthogonal cross-linked bio-ink does not cross-react with other bio-molecules, including bio-molecules that exist on the cell surface, the culture medium or the ink itself, which makes it a universal strategy.

In summary, the joint bio-ink strategy serves as a universal bio-ink platform. This strategy may realize multi-material and multi-cell bioprinting, mimic the structure of the body, and may enhance the transformation and therapeutic potential of 3D bioprinting technology.

Information source: EngineeringForLife

This information is from the Internet for academic exchanges. If there is any infringement, please contact us and delete it immediately

18915694570

Previous: "Small" by Gao Changyo