This manual is for reference only, the user can make appropriate adjustments according to the actual situation.

Product components

Composition: Porous GelMA

Mass: 0.6gX2

Storage and transportation

Dry state: Avoid light at -20��C. It can be transported at room temperature for 6 months. Solution: Protect from light at 4��C for 7 days; Protect from light at -20��C for 3 months; Repeated freezing and thawing of the solution will affect the product performance, please prepare it for immediate use.

Effective date

See packaging for production date.

materials needed

GM-PR series porous GelMA hydrogel products

PBS (1X)

Constant temperature magnetic stirring water bath

0.22 um sterile syringe filter

10-50 mL sterile centrifuge tube

10 mL syringe

1-5 mL pipette and tip

LS-1601 series 405nm flat source

The operation steps for 2D cell culture of porous GelMA hydrogel are the same as the main steps of 3D culture, except that step 3 of mixing cells is omitted. Step 6 After cleaning the sample, the cell surface can be planted.

Reminder: Do not look directly at the curing light source

Although the inside of the hydrogel also has its own pore structure, the pores are too small, which makes the internal nutrient transfer and cell metabolic wastes not smooth when the wrapped cells are subjected to three-dimensional culture and bio-3D printing. The dense pores hinder the better cell performance. Functional. In order to improve the material exchange efficiency between the cells in the hydrogel and the outside world, and to provide more space for cell growth and proliferation, the team continued to research key problems and successfully developed a high-porosity GelMA hydrogel

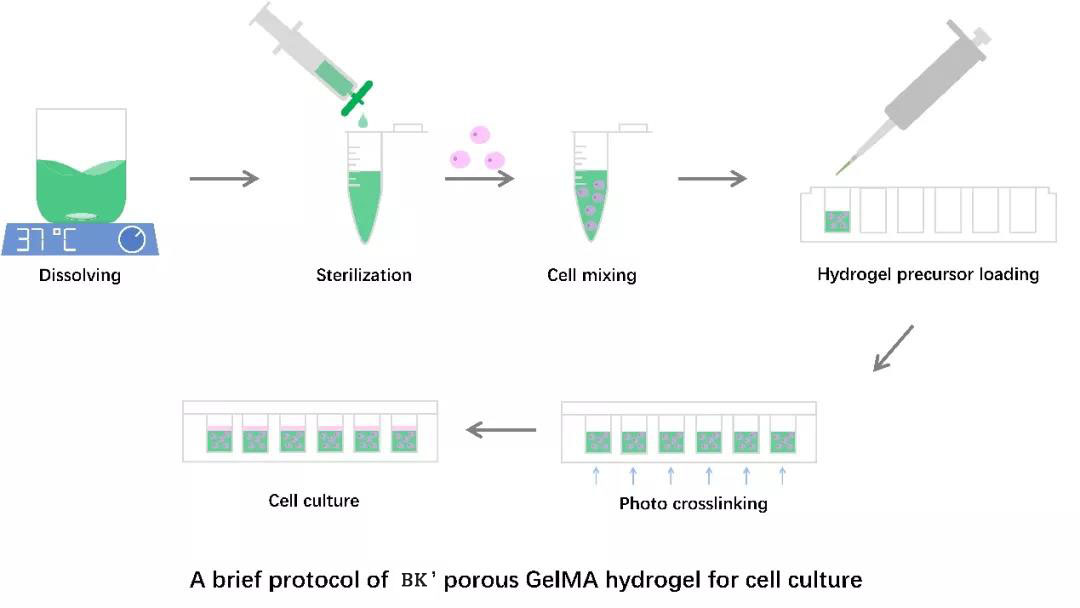

To obtain a pore structure of tens or even hundreds of microns, the conventional method is to obtain pores by emulsion. These processes have disadvantages such as poor stability and complicated operation. BKNM-GM-PR series through the subversive design of materials science, its use experience is no different from conventional GelMA materials, only need to dissolve, light curing can easily obtain hundreds of micron pore structure hydrogel (Figure 1).

Figure 1 Operation process of BKNM-GM-PR series porous GleMA hydrogel

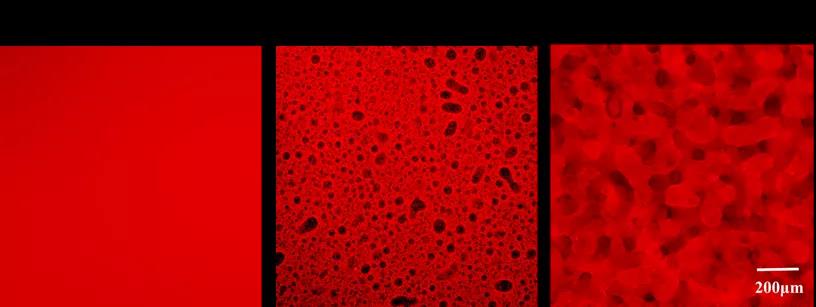

01 Micro morphology

The BKNM-GM-PR series has a pore structure of several microns to several hundreds of microns to meet the needs of different applications. Generally, a pore structure of 50 microns or more is required for three-dimensional cell culture. The large pore structure can provide efficient material exchange channels for cells, and also provide space for cell proliferation and growth, which can significantly improve cell proliferation activity. (figure 2)

Figure 2 Confocal laser photo of the controllable micro-pore structure of the BKNM-GM-PR series of porous GleMA hydrogels

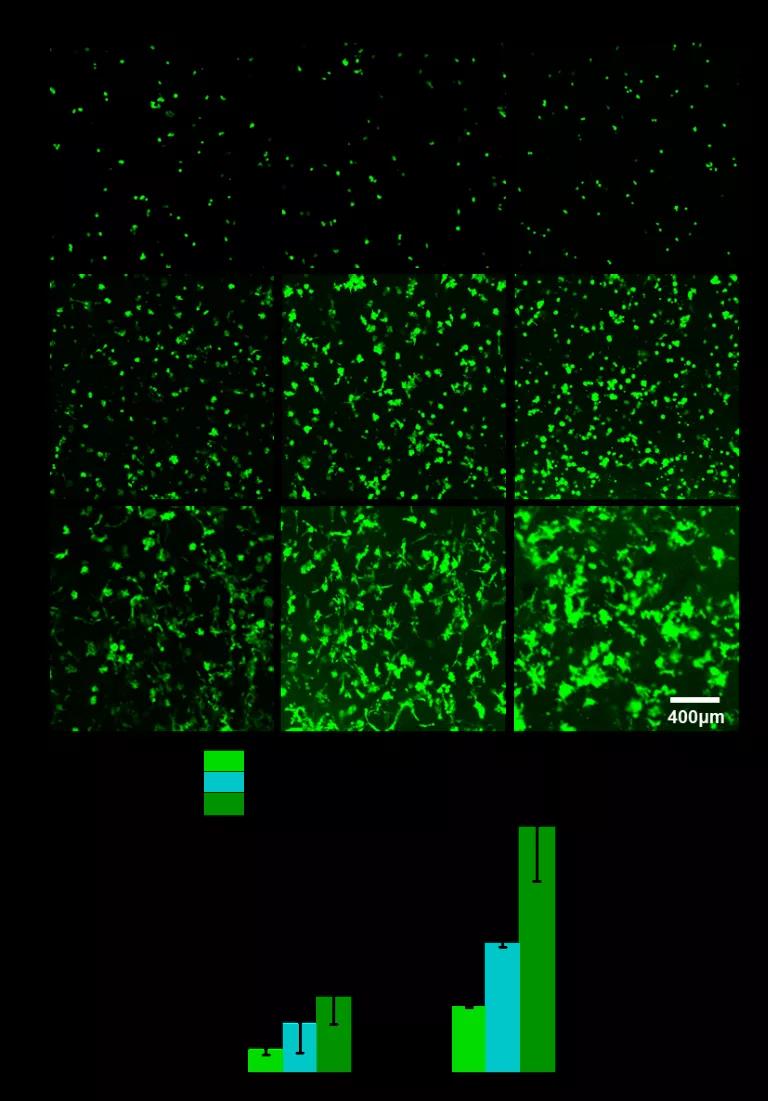

02 cell culture

The BKNM-GM-PR series of porous hydrogels have excellent performance in cell culture. The advantages of porous GelMA hydrogels can be clearly seen by comparing with GelMA non-porous hydrogels. The internal cell proliferation rate of the porous GelMA hydrogels of the two formulations was higher than that of the GelMA non-porous hydrogels, and there was a several times difference in the number of cells on the 7th day of culture. (image 3)

Figure 3 Fluorescence photo and quantitative analysis of cell proliferation inside the BKNM-GM-PR series of porous GleMA hydrogels

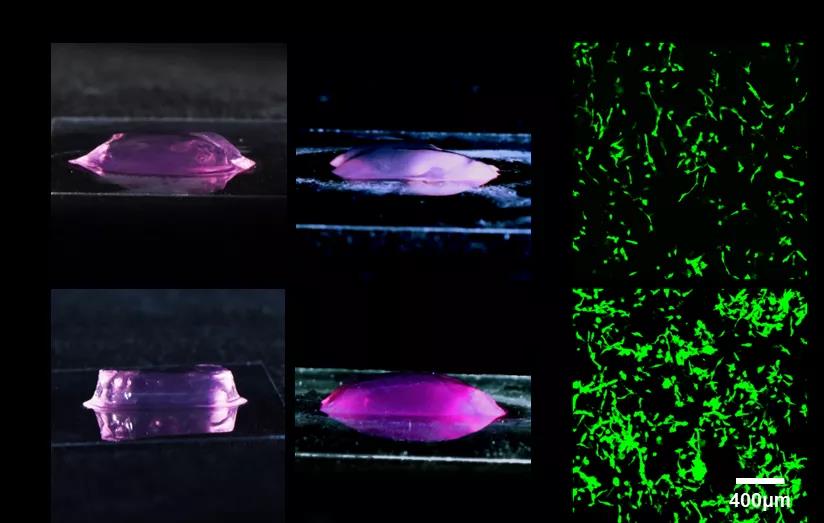

When cell culture is performed on the gel surface, the porous GelMA also has excellent performance. The perforated pore structure makes the cells seeded on the surface show a tendency to migrate into the gel, and the depth of cell migration can reach about 540��m on the 9th day. (Figure 4)

Figure 4 Fluorescence photo of cell culture on the surface of BKNM-GM-PR series porous GleMA hydrogel (red is fluorescent GelMA)

03 Stability of Hydrogel Culture Process

The specific surface area of porous hydrogels is much larger than that of ordinary non-porous hydrogels. Therefore, porous hydrogels generally degrade faster than non-porous hydrogels under the same matrix gel strength conditions. In order to support long-term cell culture, the EFL team optimized the formula to achieve excellent cell proliferation performance while giving the porous hydrogel good stability. Compared with ordinary GelMA non-porous hydrogels, BKNM-GM-PR series porous hydrogels have better performance in cell proliferation and gel stability. (Figure 5)

Figure 5 Digital photos and cell fluorescence photos of the stability test of the BKNM-GM-PR series porous GleMA hydrogel during the culture process

| Warm tips: Suzhou Beike nano products are only used for scientific research, not for human body,different batches of products have different specifications and performance |

Message

|

|

|

Scan code concerns WeChat official account

QQCommunication group��1092348845

|

|

| Warm tips: Suzhou Beike nano products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately. |